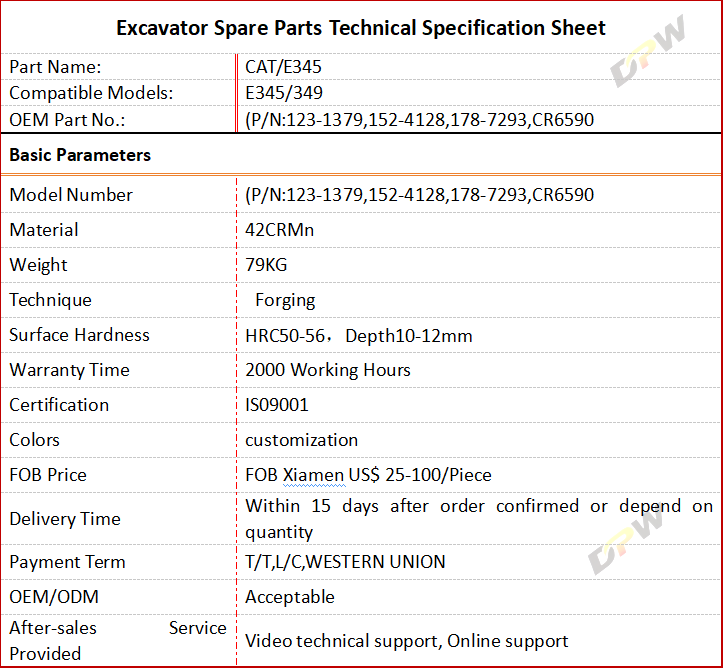

(P/N:123-1379,152-4128,178-7293,CR6590)CATERPILLAR-E345/349Track roller/Quanzhou track roller factory in China/DPW-parts

Product Specifications

(P/N:123-1379,152-4128,178-7293,CR6590)CATERPILLAR-E345/349Track roller/Quanzhou track roller factory in China/DPW-parts.

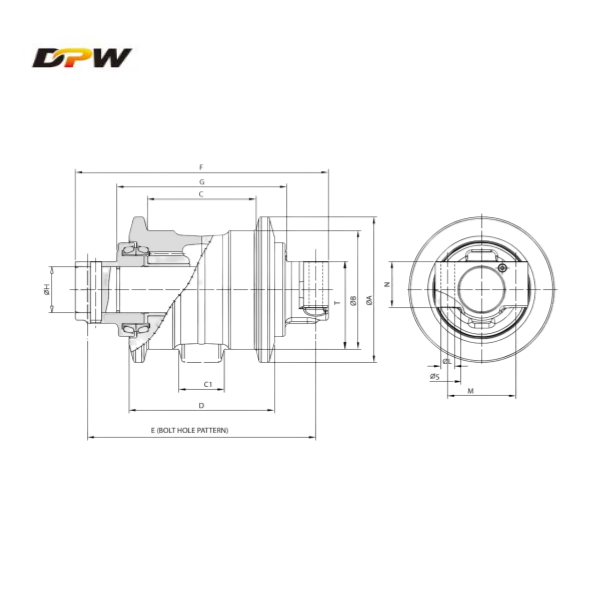

Track rollers are essential components in various types of machinery, particularly in construction, agriculture, and material handling equipment. They are designed to support and guide the movement of tracks on track-driven machines like excavators, bulldozers, and crawler loaders.

Types of Track Rollers

Bottom Rollers (Lower Rollers) – Support the weight of the machine and roll along the underside of the track chain.

Top Rollers (Upper Rollers) – Guide the track chain and keep it aligned on the undercarriage.

Front Idlers (Guide Rollers) – Positioned at the front of the track frame to help steer and maintain track tension.

Rear Sprockets (Drive Rollers) – Driven by the final drive to propel the machine.

Functions of Track Rollers

Support Machine Weight – Distribute the load evenly across the track.

Reduce Friction – Allow smooth movement of the track chain.

Maintain Track Alignment – Prevent derailment and excessive wear.

Absorb Shock Loads – Help cushion impacts from rough terrain.

Common Materials & Construction

Hardened Steel – For durability and resistance to wear.

Sealed & Lubricated Bearings – To extend service life in harsh conditions.

Rubber-Coated Rollers – Used in applications requiring reduced noise and vibration.

Signs of Worn Track Rollers

Uneven track wear

Excessive noise or vibration

Visible cracks or flat spots

Leaking grease from seals

Misalignment of the track

Maintenance Tips

Regularly inspect for wear and damage.

Keep rollers properly lubricated (if applicable).

Replace rollers in sets to ensure balanced performance.

Clean debris from the undercarriage to prevent premature wear.

Would you like recommendations for specific brands or replacement parts?